|

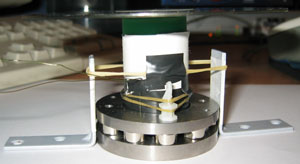

I wound a new voice coil on a former made out of card. I tried it with two layers first, but this would barely fit into

the 1.2mm airgap, so I ended up taking one layer off. The measured resistance was 2.2 ohms. Not good. I'll need to

get hold of some much thinner wire which will reduce the power handling, but that's not an issue for this project.

It's time to consider the suspension system. At least something that will hold the former in position. For a temporary

solution I

used some elastic bands.

I used a plastic lid to roll the former around. The elastic when stretched around the former was deforming it,

so I left the lid inside

to keep it in shape. An AOL cd was used for the cone. About the only thing it's good for. This was stuck down

using some blu-tac which removed the crackling noise made by the former banging against it when only tape was used.

Now I could better hear how much noise was coming from

the voice coil scraping the top plate.

One interesting point is the amount of sound emmitted from the voice coil/former alone - without a cone. There was

little difference when attaching a cone relatively speaking. This makes me wander how much the spider, former and

vibrations in the magnet assembly contribute to the sound in commercial transducers. They clearly add to the

sound produced by the cone surface but I've never heard anyone speak of the sonic effects of say, an aluminium former.

Could this be another reason for choosing one former material over another?

|